What Is The Proper Method to Torque Wheel Lug Nuts Or Bolts?

(Lea en español)Proper wheel installation requires the wheel-attaching hardware (lug nuts or bolts) be tightened to the recommended torque specification for the vehicle make, model and year. Torque specifications are usually found in the vehicle's owner's manual.*

Proper torque requires using the correct tools, procedures and patterns. These will prevent over-tightening the hardware, stripping the fastener threads, and stretching the studs. It will also reduce the possibility of warping the brake drums, rotors or hubs.

Under- or over-tightening wheel-attaching hardware can be damaging and dangerous.

Torque specifications are for dry threads only. The fastener threads should be free of oil, dirt, grit, corrosion, etc. The hardware should turn freely without binding when tightened by hand. It is important NOT to lubricate hardware threads or seats. The friction at which torque is measured against should come from the hardware seats. Lubricating hardware threads and seats alters the friction generated at the lug seat which will result in inaccurate torque readings and/or over-torqueing of the hardware.

We recommend starting hardware by hand, snugging them manually and then using a beam or click-type torque wrench to apply the final torque in the correct patterns shown below to confirm the recommended torque value has been reached.

We do not recommend using impact guns or torque sticks when installing wheels. Impact guns can damage hardware and wheel finish. Some vehicles, such as Porsches, require the use of special sockets to tighten the hardware without damaging their anodized coating. Impact gun torque can vary widely from low torque (resulting in loose wheels) to extremely high torque (resulting in damage or broken hardware).

Some of the variables that can cause inaccurate torque delivery:

- Type of impact used (air, electric, cordless)

- Power (air pressure, air volume, length of hose, size of fittings, battery power, battery age)

- Impacts per second

- Size of internal hammers

- Possible use of additional adapters

- Socket size, weight, length

- Operator grip strength

- Weight of the impact

- Applied angle during use

Attempting to fully tighten hardware with impact guns/torque sticks also prevents using a click-type torque wrench to confirm the specified amount of torque is present. While a click-type torque wrench can identify when the selected torque has been reached, it cannot diagnose excessive torque.

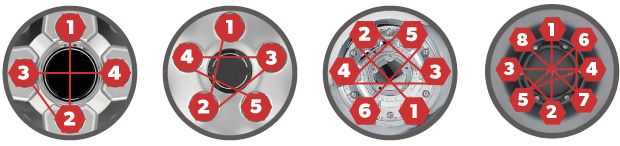

Once you have the right tools, use the appropriate crisscross sequence (patterns shown below) for the number of the vehicle's wheel-attaching hardware positions until all have reached their specified torque value.

Tightening and Loosening Patterns

New wheels should be re-torqued after the first 50 to 100 driving miles.

This should be done in case the clamping loads have changed following the initial installation due to the metal compression/elongation or thermal stresses affecting the wheels as they are breaking in, as well as to verify the accuracy of the original installation.

When rechecking torque value, wait for the wheels to cool to ambient temperature (never torque a hot wheel). Loosen and retighten to value, in sequence using the torque procedures listed above.

*If you cannot find the vehicle manufacturer's recommended torque spec, you can use the following as a guide.

| Hardware Bolt or Stud Size | Typical Torque Range in Ft/Lbs | Minimum Number of Turns of Hardware Engagement |

|---|---|---|

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 9 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |