Servicing Direct Tire Pressure Monitoring Systems

Since tire pressure monitoring systems (TPMS) are a relatively recent addition to most vehicles, it's important to know which vehicles are equipped with TPMS and recognize what types of sensors are used. It is also important to check for aftermarket TPMS installed on vehicles, as well.

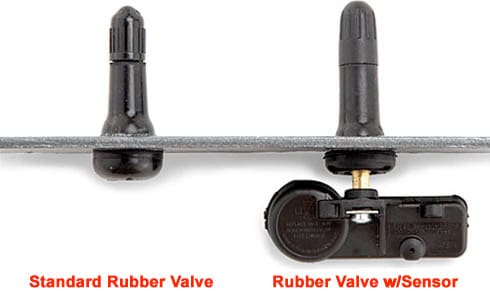

The presence of standard rubber valves in the wheels normally indicates the vehicle uses an indirect tire pressure monitoring system that compares tire revolutions when the vehicle is in motion by monitoring the ABS speed sensors. However, beginning with the 2007 model year, some vehicles have begun using a rubber valve stem direct TPMS that is hard to distinguish visually from a standard rubber valve stem. Only the rubber TPMS valve's resistance to gentle bending confirms its design.

The presence of aluminum valve stems bolted through the wheels normally indicates the vehicle uses a direct TPMS in which pressure sensors/transmitters are attached to the wheels.

However, some earlier Corvettes and recent Ford vehicles have direct tire pressure sensors banded to their wheels.

Aluminum Valve Sensor

Ford Banded Sensor

If a direct TPMS system is in use and the air pressure has been released from the tire, the aluminum tire valve (along with its attached tire pressure sensor) should be unbolted and allowed to gently "drop" into the still-mounted tire and wheel. This will help protect the tire pressure sensors (some exceeding $200 each when purchased from a new car dealer) from being broken during bead loosening and tire dismounting

The tire should be removed from the wheel following the tire machine's instructions.

Before the tire is reinstalled following the tire machine's instructions, all original TPMS aluminum sensors should be fitted with a new rubber grommet (also called an o-ring or seal), aluminum retaining nut, special nickel-plated valve core and O.E. valve cap.

Rubber Grommet, Aluminum Retaining Nut, Special Nickel-Plated Valve Core and O.E. Valve Cap

It is important that all components be torqued to appropriate values to prevent air leaks. Attempting to reuse the original rubber grommet, valve core and retaining nut may result in an air leak. Additionally, it is important to retain the original aluminum TPMS sensor's valve cap.

Note: A standard brass valve core used in an aluminum tire pressure sensor valve stem will experience galvanic corrosion and the brass valve core will eventually seize in the valve's aluminum barrel.

Only special nickel-plated valve cores should be used in aluminum tire pressure sensor valve stems.